Model No.︰Customize

Brand Name︰-

Country of Origin︰China

Unit Price︰US $ 2983 / set

Minimum Order︰1 set

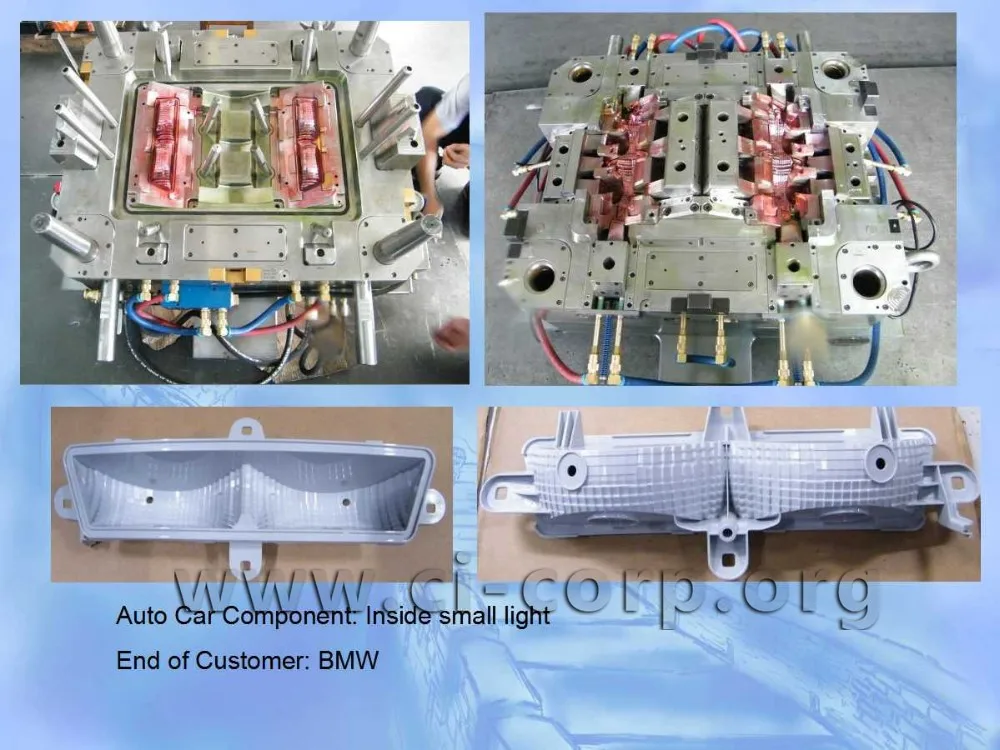

Description of mould:

Material of core and cavities: P20,718, or according to customer's request

Mold base: LKM and HASCO

Injection type: pin-point, tunnel, edge, fan and sprue gate

Mold type: normal, hot runner and air assistance

Machining: advanced CNC, EDM Wire-cutting, milling machine, grinding machine, lathe etc

Features: high accuracy and durable

Mould life:100,000 -10,000,000 shots

Company Information:

Established in 1995 and located in the mould manufacturing base of ShenZhen—BuJi Town, CREATIVE

INNOVATIVE CO., LTD is a big-scale professional mould enterprise, who engages to design and

manufacture moulds. With our continuous development, we own more than 45 sets of various advanced

numerical controlling machines, such as CNC machines, EDM machines, Wire-cut machines etc. We have

20,000 square meters factory area, 140 experienced toolmakers and our annual productivity reaches to

500 sets of moulds, and over 80% moulds are exported to Europe, American etc all over the world.

There are 2 major branches of our factory—(1) the precision mould manufacturing center and (2) the big-

size mould manufacturing center. Our excellent and well-experienced designers and engineers use the

most advanced software i.e. CAD/CAE/CAM, helping us to produce the best molds accurately and rapidly.

We also have 3D measurement Machines and Laser Scanner in our Quality Control Department which

helps us ensure the best quality, reliability and consistency of our moulds.

Our Services:

. After receiving customer’s 2D/3D drawing, our engineers will evaluate and design part mould for clients.

. Rapidly prototype mold is available

. Specialized engineers work for order track and sales follow up, they are always ready for customer service.

. OEM service

. Surface treatment (Vibratory finishing,Passivation,Painting & Electroplating)

Why Choose CI:

. Goodunderstanding of Customer’s Requirement

. Class “A” Quality

. On Time Delivery

. Shorter Manufacturing Process

. High-Efficiency Communication

Mold Shop

Injection Floor

Trade Shows

Payment Terms︰ T/T